Level of analysis: Micro

Assessed aspects of sustainability: environmental, economic

Main purpose of the assessment:

To economically optimize a production life cycle with environmental goals/constraints.

Description of the methodology:

Life Cycle Activity Analysis (LCAA) is a methodology developed by Thore and Freire (1999) to combine classical activity Analysis (AA) with environmental Life Cycle Assessment (LCA). It provides a computable approach to economic and environmental optimization of the supply chain of products, processes or services. LCAA considers all activities from ‘cradle to grave’ including alternative methods of production, distribution, reuse and recovery.

Detailed Description

LCAA combines mathematical programming of Activity Analysis with the LCA methodology. AA was developed by Koopmans (1951, 1957). The original formulation, (Koopmans, 1957), was not well suited for numerical solution, since it assumed that there were as many commodities as activities, and that the resulting system of equations had a non-singular solution. The reformulation of AA as a Linear Programming (LP) problem, permitted any number of activities and any number of commodities, (Charnes and Cooper, 1961). Activity Analysis can be viewed as a tool of partial economic analysis modelling for the representation of an industry or a sector of the economy, providing a mathematical format suitable for the representation of an entire vertical production chain (Thore, 1991). More recently, Heijungs (1996, 1997) recognized the conceptual similarities between LCA and classical Activity Analysis (AA) and observed that Life Cycle Inventory is an extension of AA, both being “commodity-by-industry analysis”, however no connection between mathematical programming and LCA was made. LCAA presents a methodology to use mathematical programming formats of AA for integrated economic and environmental analysis of the life cycle of products.

The classical formulation of AA distinguishes three classes of goods: primary goods, intermediate goods and final goods. LCAA extends the concept of linear activities to cover mass and energy fluxes over the entire life cycle of products. Furthermore, LCAA includes an additional category: ‘environmental goods’, representing primary resources (material or energy drawn directly from the environment) and emissions of pollutants and the disposal of waste (discarded into the environment without subsequent human transformation). These are in the LCA terminology known as environmental burdens. The environmental ‘goods’ can be further aggregated into categories of resource usage and environmental impacts, such as global warming, ozone depletion etc.

Mathematical formulation

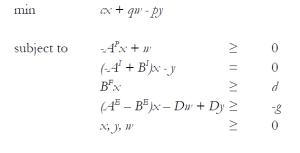

Similar to LCA, LCAA uses the concepts of a foreground and background system. The foreground is modelled in detail including the production activities themselves and the conversion of intermediate goods into final goods, i.e. all processes whose level of operation can be affected directly by decisions in the study. The background comprises of the exogenous flows of the model, i.e. the supplies of primary goods. The system may have two closed loops in the foreground; an inner loop returns goods to direct reuse, and an outer recycling loop returns materials from used final goods back to remanufacturing. In addition, goods can also be recycled in the background (open loop recycling). In LCAA a product that is recovered and exchanged with the background system will always be treated as an intermediate good. LCAA is based on the input-output table format. The LCAA format is represented as (Freire et al., 2002):

where cx represents the total costs of operating the activities x (column vector of activity levels), qw represents the total cost of primary goods w (column vector of supply levels of primary goods), and py represents the net revenue or cost of “exporting” intermediate goods to the background for reuse or recovery. p is a vector of unit prices of recovered goods and y is a column vector of unknown levels of recovery of intermediate goods. A and B are matrices of input and output coefficients, respectively and the superscripts P, I, F and E stand for primary, intermediate, final and environmental goods, respectively. Environmental goods or interventions are materials or energy drawn from or discarded into to environment without subsequent human transformation. By convention inputs have a negative sign and outputs have a positive sign, giving the matrices A and B the form:

Primary goods account for products, materials and energy produced in the background system, entering as inputs to the foreground system. Intermediate goods are outputs that serve as inputs into subsequent activities, either in the fore- or background. Final goods are the functional outputs delivered by the distributed and purchased products/services, the production of which is the objective of the economic system being studied.

The first constraint above forbids the amount of primary goods to be higher than what exists in stock. The second constraint gives the market balance for intermediate goods; the output of intermediate good equals the sum of intermediate inputs and recovered goods. The third constraint simply guarantees that demand is met. The fourth constraint takes in to account environmental burdens; the total environmental burdens are equal to the sum of foreground (direct) burdens, (AE – BE)x, ,and the background (indirect) burdens, Dw, minus the avoided burdens, Dy. Finally all activities, recovery rates and supply levels must be non-negative.

Environmental impact assessment is done similarly to standard LCA. A vector of environmental burdens, E(i), is equal to the sum of all direct and indirect burdens minus avoided burdens: E(i) = (BE – AE)x + Dw – Dy , where i represents individual environmental burdens. The individual burdens can be aggregated in to a set of environmental impact categories: I(j) = F(j,i).E(i), where I(j) is a vector of impact categories and F(j,i) is a matrix of relevant impact coefficients. A goal-oriented expression for the fourth constraint can be formulated as:

F(j,i) .[(AE – BE)x – Dw + Dy] ≥ –g’

where g’ is a vector of goals defined in terms of environmental impact categories.

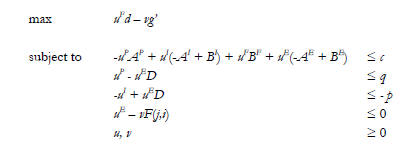

It is also possible to define the optimization problem above in a dual programming format:

where and v are the dual variables. They may be interpreted as the shadow prices of primary, intermediate, final and environmental goods and of the environmental impact goals, respectively. The dual model aims to maximize the shadow value of the final goods calculated net of the shadow costs of environmental impact goals. The first constraint states that the imputed cost of operating an activity cannot exceed its direct cash cost. The second constraint states that the shadow cost of primary goods cannot exceed its market price plus the environmental shadow cost. The third constraint states that the shadow value of an intermediate good exported to the background cannot fall short of its market price plus its imputed environmental shadow cost. The fourth constraint states that the shadow cost of an individual environmental burden cannot exceed the imputed cost of the environmental goal in the corresponding impact category.

According to the dual theorem of linear programming, the value of the prime at optimum equals the value of the dual program:

cx + qw – py = uFd – vg’

This means that the total net cash costs plus the shadow costs of environmental impact goals equal the shadow value of the final goods. It is assumed that all markets will be in equilibrium and the shadow costs of the goods represent competitive market prices. The shadow costs of environmental impact goals can be interpreted as environmental fees or excise taxes. This means that rather than aiming for environmental goals directly, the alternative would be to introduce environmental fees designed to implement the environmental goals g’. These mathematical models assume linearity, which is quite acceptable when the life cycle of the product being modelled induces only marginal changes in the activity levels. However, if specific aspects of the life cycle are acknowledged as non-linear, then non-linearity has to be introduced and defined mathematically in an appropriate manner.

Advantages

The LCAA approach offers the following advantages (Freire et al. 2001):

– LCAA is a numerical technique, facilitated by the use of mathematical programming software. A software used for several LCAA case studies is GAMS (General Algebraic Modelling Software),

– LCAA explicitly recognizes the possibility of alternative ways of production, alternative distribution channels, and alternative reuse or recovery processes (the programming model determines the optimal choices).

– LCAA incorporates techniques for representing environmental goals in the model, in the so-called Goal Programming. These goals do not need to be absolute targets but can be a set of ordinal priorities, laid down by decision- or policy-makers.

– In LCAA (unlike in LCA) there are mathematical degrees of freedom present, since vectors of individual environmental burdens associated with alternative activities may translate into the same aggregated impacts. The optimizing format makes it therefore possible to determine the optimal levels of individual environmental burdens (and associated vector of activity levels) that are commensurate with a given set of goals in terms of environmental impact categories.

LCAA has been applied to several typical LCA systems, such as plastic panels (Freire et al, 2002), used tires (Freire et al 2000), bottled water (Freire et al 2001) and biofuel production (Freire et al 2002).

Strengths

Scope of assessment (what is being assessed)

The scope of LCAA is detailed at the micro-level, by design compatible with a typical LCA scope. In addition the background system is taken in to account for environmental burdens e.g. for recycling occurring in the background system. LCAA has the advantage of taking in to account both economical and environmental aspects in a coherent way, demonstrating clearly e.g. the economic implications of change in environmental goals. Thus LCAA has a strength in economic-environmental trade-off analysis, which can be taken advantage of at the EU research level.

Methodology (robustness, validity & reliability)

As LCAA is strongly based on established methodologies, it is built robust, valid and reliable within its scope. All results are quantified and can be traced to the sources. Also a sensitivity analysis is easy to perform due to the methods computable format.

Weaknesses/Limitations

Scope of assessment

LCAA in its current format is designed to be compatible with ISO-LCA, having some of the limitations that LCA has when it comes to applicability to other than micro-level products and services. The method at present does not include social aspects. Also, due to its limited scope, some relevant aspects may be overlooked in an LCAA study if directly applied to complex systems.

Methodology

Equally, when it comes to methodology, the limitations of LCAA are basically those of its constituents; LCA and AA. In the economic analysis, equilibrium is assumed between demand and supply and all relationships are assumed to be linear (although the possibility to formulate non-linear relations is mentioned). In the environmental aspects, as in ISO-LCA, the assessment is limited to the scope of the chosen impact assessment method.

EU research design can help overcome the weaknesses mentioned here by assuring the use of complementary tools, for the study of aspects not covered by LCAA (meso/macro level systems analysis, social aspects).

Opportunities for broadening and deepening LCA

LCAA is a concrete step to the inclusion of economic aspects to LCA. It has the potential to be used for the study of trade-offs between alternatives e.g. various environmental goals. It also has the possibility, by its mathematical structure, to include some social aspects, such as jobs created or lost.

Within EU research, LCAA offers opportunities in local policy analysis and decision making taking in to account environmental goals, while economically optimizing the system.

Threats for broadening and deepening LCA

The method at present does not include social aspects. Also, due to its limited scope, some relevant aspects may be left outside. At the level of EU research, the clearest threat to LCAA is its limited scope and its being a relatively unknown method.

Literature/Internet links

Freire, F., Thore, S., Ferrão, P., 2001, Life cycle acticity analysis: logistics and environmental policies for bottled water in Portugal, OR Spektrum 23: 159-182.

Freire, F., Williams, E., Azapagic, A., Clift, R., Stevens, G., Mellor, W., 2002, Life Cycle Activity Analysis and the Case Study of Plastic Panels, published in the book: TechnologyCommercialization: DEA and Related Analytical Methods for Evaluating the Use andImplementation of Techical Innovation. Thore, S. (ed). Kluwer Academic Publishers, 2002,pp. 323-352.

Freire, F., Ferrão, P., Reis, C., Thore, S., 2000, Life Cycle Activity Analysis Applied to the Portuguese Used Tire Market, Journal of Passenger Car. Mechanical Systems. SAE Transactions 109: 1980-1988.

Freire, F., Malça, J., Rozakis, S., 2004, Integrated Economic and Environmental Life Cycle Optimization: an Application to Biofuel Production in France, Multiple Criteria Decision Aiding/Aíde Multicitère à la Décision. C. Henggeler Antunes, J. Figueira, J. Clímaco (Eds.). ISBN: 972-569-140-7. Refereed Selected papers from the 56th Meeting of the European Working Group Decision Multiple Criteria Decision (2002).

Heijungs, R., Identification of Key Issues for Further Investigation on Improving the Reliability of Life-Cycle Assessments, Journal of Cleaner Production, 1996, 4:159-166

Heijungs, R., 1997, Economic drama and the environmental stage. PhD Dissertation, University of Leiden.

ISO 14042, “Environmental management – Life cycle assessment – Life cycle impact assessment”. 22 ISO (International Organization for Standardisation), 1998.

Koopmans, T., Analysis of production as an efficient combination of activities, in: T. Koopmans (Ed.), Activity Analysis of Production and Allocation. Proceedings of a Conference.

Cowles Commission Monograph N. 13. John Wiley, New York, 1951, 33-98.

Koopmans, T., 1957, Three essays on the state of economic science. McGraw-Hill, New York.

Thore, S., 1991, Economic logistics: the optimization ofspatial and sectoral resource, production and distribution system, Quorum Books, Westport, CN.